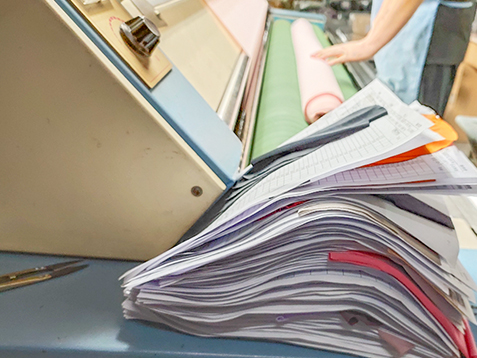

Fabric Inspection When the fabrics arrive at the warehouse, we will do fabric inspection, the photo is to show the fabric is being inspected by our fabric inspection machine. At the side, there is an inspection book that is to record which fabric to inspect, the inspection result etc. We normally inspect fabric at 4-point system. And we do many fabric tests as customer request on color fastness or chemical test.

Factory auto-machine production lines ACTEX is factory, we have 2 own factories. One is underwear factory which have 800 skilled workers. The other is swimwear and activewear factory which have almost 500 skilled workers. Our udnerwear factory have normal sewing lines for quality bra and panties and seamless workshops for quality seamless underwear and seamless activewear. Our swimwear and activewear factory have normal sewing lines and auto-machine production lines. Here is showing the picture of our auto-machine production lines from our swimwear and activewear factory in China. They are processed under BSCI audit standard. Normally, if order qty more than 3000pcs per style per color, the products will be made by these auto lines to get the competitive prices and better shipment date than normal production sewing lines.

Factory seamless product workshops Attached is showing part of our seamless products workshops for underwear and activewear in different sizes. We are professional seamless underwear manufacturer in China and seamless activewear factory. We can make the seamless products in different designs as your sketch or your original samples. We also can send you our samples for your choosing. Welcome any OEM or ODM orders.

04 Factory Packing From the picture, it is part of our packing deparments for our custom underwear factory. After final inspection, all the goods will be ironed according to styles or request, and then packed as customers request with the hangtags, hangers, polybags, cartons etc..

05 factory inspection As a professional maufacturer in underwear, swimwear and activewear, all the goods we made needs to be inspected strictly as request. When sampling, we have sample inspectors to check if the samples are made as buyers' requests or any issue on patterns or workmanships etc.. Before the bulk production, we always have pre-production meeting and pay attention on every detail to make sure bulk production smooth. When start sewing, we will make the first several pieces of bulk to check if any problems. And we also have mid-line inspectors to check semi-production. When finished goods, our final inspectors will inspect the finish goods one by one based on AQL standard. Here attached is one picture of our inspection, as shown, our final inspectors wear the finished quality womens underwear on the acrylic board to flat the good quality underwear well, make it easy to inspect the goods to avoid missing any defect.

Factory normal sewing production lines ACTEX is factory, we have 2 own factories. One is underwear factory which have about 1000 skilled workers. The other is swimwear and activewear factory which have almost 1000 skilled workers. Our udnerwear factory have normal sewing lines for quality bra and panties and seamless workshops for quality seamless underwear and seamless activewear. Our swimwear and activewear factory have normal sewing lines and auto-machine production lines. Here is a picture to show one floor of our normal sewing lines. For the underwear with seams or the orders of swimwear and activewear in small qty or complicate workmanships etc., they will normally be made by the normal sewing lines by our skilled workers.

Factory no show panty iron machine Here is to show one machine for our no show underwear. After cutting fabric as patterns, we will iron the joint seams by normal ironing machines at first, and then use attached no show iron machine to press the no show underwear for several minutes to reinforce the joint seams.

Factory metal detector Attached is showing the packed goods pass the metal detector before packing into the cartons. It is very important for underwear and kids goods, or any goods which contact with the skin directly. If any goods failed, they will be sorted out as defect ones and the detect results will be recorded into the metal detector calibration record books at once.

Fabric warehouse There is a picture to show some part of our fabric warehouse. Each roll of fabric is packed with plastic bag with stickers at sides which marked the fabric item, the composition, the arrival time etc.. And different fabrics for different customers will be stored separately on the fabric shelves. In this way, the fabrics can avoid to get dirty or moistured. Besides, there is a fabric storage book at the side of every layer of fabric shelves to record the fabric details which are stored at this layer.

1

22

pagesCopyright © 2024 XIAMEN AC TEX INDUSTRY&TRADE CO.,LTD.. All Rights Reserved.

IPv6 network supported